Bernd Brück from Germany , a German Zimmermann (Carpenter), sent me a PDF file with the story of rebuilding the Leaning Tower of Mayen after world war 2. It's pretty interesting, on how the roof framing geometry is designed by rotated and offset Octagons, which in turn forms the leaning twisted spiral tower.

I've translated the German text to English with the Google Translator.

_____________________________________________________________________

_____________________________________________________________________

The Leaning Tower of Mayen

Der schiefe Turm von Mayen

Post 1 January 1953

A unique carpentry task

When speaking of crooked and twisted spires, the name Mayen will

always fall. In a number of publications, the "German Master carpenter

"about this unique ancient monument reported in the bombing of the last

war, with a large part of the Old Town,

this sexy Eiffel tower rubble fell.

The Mayener are tough. Thus grew because soon after the war the

tower walls of St. Clement's Church again in the sky, only the spire, the

crowning of the building, was still missing. In the spring of vergangenen Year

it came down to it, that one is more detailed thoughts about his design made.

Some were for a new, straight-building;

However, the majority of Mayener wanted known landmark of Mayen,

the "leaning See built on · again. Ancient form tower ". For a

version in steel, to which one first had thought, in particular the men turned

·Gehrüder Rosenbaum, Zi ~ ergeschäft and sawmill in Mayen, the later the

execution of the new wooden tower Helms took over. Design and static

Calculation was in the hands of the Consulting in Karlsruhe. Was originally

thought only the rotation of the spire to restore and to refrain from the Uber

slopes of the peak, so should now be the new spire of the old as possible

same.

Well yes Turmkons constructions anyway not an everyday Task, but

twisted and crooked already not at all. According to the literature on

verdrehte towers it's almost been exclusively design flaw, led to deformation -

such had of course, be avoided. Only about a 100 year old work, "The work

of art in all rooms its parts "vori Andreas Romberg, we could remove some

recb.l valuable information.

The author has sieve in this extensive Bum also with the.,

Construction wooden Thunuspit ~ s "concerned and a number heed cheaper

receivables aufgestellt, of which we will mention only a few. So should the

construction in Inner possible glues held however, the roof panels are

self-reinforced to the commission of the tower and the later ere control the

components not to unnecessarily obscure; the Longitudinal forces should only

end grain to end-grain be rendered in order not dUrd: l uneven Subsidence occur

later Vertormungen; according to several years overdue repair work is it width

that all woods are connected so that they can be easily replaced without di ~

Star: dfestigkeit of the building while impaired ~ ud. Hmzu came in the case

Mayen still the verständhche Request of the executive master carpenter by

Aufrichtarbeit easier.

The result of all considerations led us first to two designs. The

first draft was the roof sheathing used for carrying with it So was a nailed-shell

structure; scheduled were 8 struts, on which at a distance of about 80 cm

planks nailed wreaths are placed should. The advantage of the light and the

Abbunds extensive adaptability to the shape of the old spire stood but they

also have disadvantages. So have the quest, as they no shock to Break point had

to be carried out, a large obtain overall length and makes the erection;

the upper part of the tower would be because of the Anhäufunq of

structural timbers at the break point not from the inside been accessible;

Finally, it would later have may be adversely affected during repairs, down

when D1E whole construction into the roof had.

For this reason, we chose the second design, the design shown, -

everyone could connect receivables in happier ways.

The Rising masonry has an exterior of rd. 6.45 X 6.75 m,

that is not exactly square. to the supports of the belfry - a reinforced

concrete ring beam, of 24m above the ground is - is the wall thickness of 1.00

m. Furthermore rise in the four sides of the tower, the 70 cm thick pediments

with the scarf holes. From Glockenstuhlauflager to up the gable peaks are 6.00

m. The wooden tower construction consists of a lower part with joists above the

belfry; also rises the real helmet with a height of 21.00 rn., it is divided

into 5 equal floors, each 4.20 m.

The substructure is the Dbergang of the square base of the tower

to the eight-vertex of the helmet. The outer diameter of the octagon

circumscribed circle was 6.60 m laid down; the difference - which arises from

the fact that the superstructure regularly, the base is irregular - was settled

by the roof membrane, since otherwise have been without the vevgrößert! ün

existing difficulties in joinery unbearable would.

In the tower corners and in the middle of the tower walls are in

the area of the bell chair Post net and arranged by joists

and ceiling joists connected to. The in Middle wall standing posts (Fig. 1) are

in each case by two struts on the corners the tower sought. In the tower

corners are strut post after a slight angle

to put inside the tower and connected to the corner posts by short

Pliers: wear an octagonal section steel rafters, the remaining four corners

support equipment to the concrete by reinforced gables rest. The frame measures

transmits the loads on the upper Turmkon-construction (Fig. 2) on the bottom

and takes the here

ensuing horizontal forces. Here in the gable-triangles and

anchored to the corner posts. The corner post in turn anchorages integrated

into the reinforced concrete ring beam.

The upper part of the tower construction, the actual helmet is

made, on the one hand from the supporting structure with the Pfettenkränzen and

partly from the rafters with the roof skin (formwork, cardboard, slate). For

the first three floors above profile steel frame is selected a network whose

vertices per floor 1/16 are shifted from each other so that the ridges perform

the desired rotation. The two lower floors are centrally übereinan the while

the third is already 20 cm to the east ver-Is' choben!. From the third floor up

to the helmet tip no more distortion is present. Here were the Füllhölzern of

goats on the third floor of the pursuit of the Kaiser handle high out. The

spire hangs by a total of 1.40 m to the east.

The key to the whole construction are the goats of the lower

floors (Fig. 4 & 6). They are re regularly, ie the two trestle legs are of

equal length and nestle Up to a Füllholz to with which they each by two and two

hardwood dowels (Bearing capacity speed about 1000 kg), respectively. In this

way, it was possible not only by all of the loads To transfer grain to grain,

but but also considerable tensile forces within the include construction, are

expected to arise in particular because of the one-sided tilt had.

Each floor encircling Pfet are tenkränze (Fig. 4 and 5) and each

one crosswise stiffened bottom (Fig. 3) arranged net whose stiffeners also

cables with nozzle are connected. The floors are strong up to a manhole with 3

cm, strong nailed floor coverings provided.

From the Füllholz of goats on the third floor of läilfen after

Helmet tip struts halfway again by a recent purlin

held together ten are at the ridge and out of the bolt and

components are connected by more a keyed round steel ring be taken. The struts

for receiving twisting forces with Andrew's crosses in 4 levels verschwertet.

Because of the inclination of the upper part of the helmet was the

only otherwise required above Kai serstiel up in the covering over the bell

chair brought down; thereby became even better achieved anchorage.

The entire construction including the roof sheathing is with a

proven Wood preservatives · salt impregnated on base in the immersion process

short.

The belfry itself was a steel-construction carried out.

The Abbundarbeiten were not like at such a fancy design is to be

expected, not very easy. In contrast, the erection went larly proportionate

very painless; that was not last well on the exemplary work stand and the

spacious work platform at the level of the summit peaks. Woe: lort

stood up, did not in any event the impression that he is already SID1 be

30m above the ground.

Each timber had been overcome with the help of a construction and

electric drive pulled up. According to which the lower part of the construction

of the tower, inside and auf.gestellt the profile frame was attached in

pairs-the bucks of the first floor were each represents and connected by the

Aussteifungshölzer with the Emperor stalk. Similarly the next two stories were

set up what essentially without zusätzlidle Scaffolding could go on. The

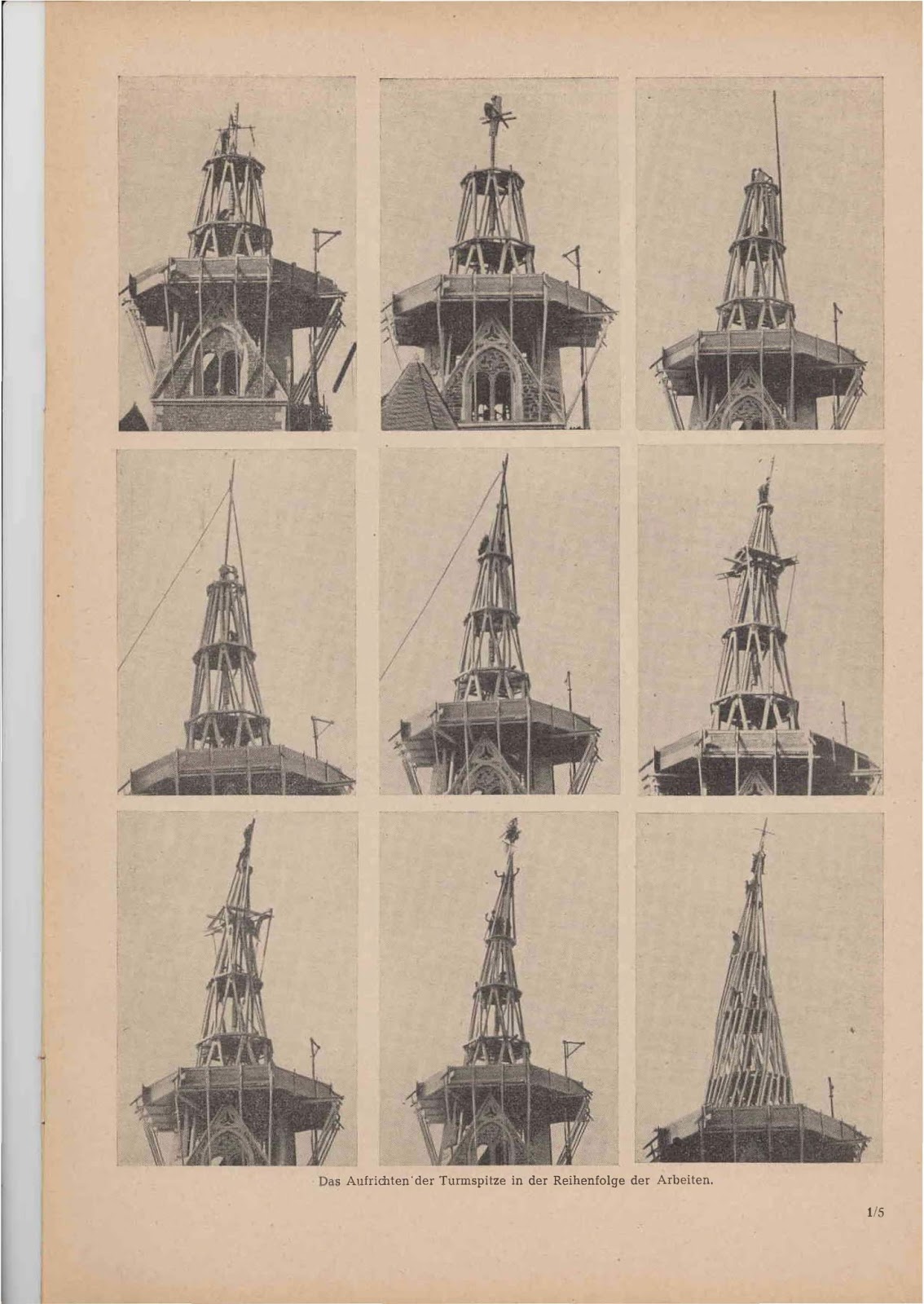

setting up of the third and the overlying Floors can be seen alfs the attached

pictures.

To align the struts and the Imperial stem still an auxiliary mast

had to be made. From the series follow the images is clearly evident how this

issue on the individual has been resolved. Above the third floor was to carry

out the further Are work even created a small work platform, because the space

there, as also from

the pictures shows it was no longer too plentiful. Finally, were

the top attached the rafters down, with at each purlin flat steel anchors are

fixed, and finally in the order gleidler are, and finally in order the

gleidler applied formwork.

The Reconstruction went smoothly and without any accident

withstanding. Meanwhile, the building has been in the first violent storms

proved. Let's hope that the tower in the future all storms withstand and an

equally venerable age reaches its like before predecessor.

The check digit on cutters

Large cutters, Abplattköpfe, knife shafts, slotted discs, etc.

carry in most cases the

Approval of the factory producing factory, for example, n = 4000.,

This means that the concerned Fende

Tool has been tested for safety in a one-minute speed of 4000.

., N "is the technical term in the calculation formulas for

every minute rotational speed of the tool, ie., n = 4000 "means 4000 every

minute rotations of the Tool.

Since this check number, the maximum allowed speed in Indicates

idle, every minute must the tool concerned with more than 3000 Run turns.

Dignity., N= To work 4000 ", then would the tool cut excessively and will

burn hot. · The rotation speed may therefore only be höd1stens 3/4 be the

specified check digit. Importantly, the tool factory in order is placed

indicating the speed of the engine.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.