Here's the ground plan for the task model with the profile rafter and the heights-locations of the crossing rafters.

Added the hip rafter profile.

This task model is similar to the Schräge Sparren model where the top edge of the hip rafter is beveled in one direction only.

Here I developed the roof surface.

In this next drawing I drew out the backing angle for the hip rafter and I also used the rotated rafter block to determine the dimension of the internal edge of the hip rafter on the real roof surface. Then I drew some perpendicular lines to the crossing rafter on the roof surface to develop the miter angle of the crossing rafter.

The crossing rafters are 40cm x 40cm. Use a 40cm x 40cm rafter block perpendicular to the hip rafter backing triangle to determine the dimension for the internal edge of the hip rafter on the roof surface that is drawn parallel to the edge of the hip rafter on the roof surface.

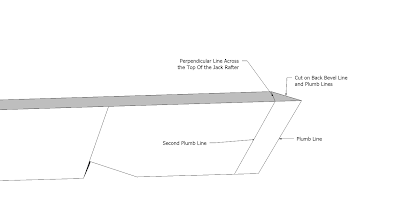

This is a 3D drawing of the crossing rafters. When two rafters are perpendicular to the roof surface, the miter angle on the side of the crossing rafters is 90°.

Here I'm checking the miter angle of the crossing jack rafter at the foot of the crossing rafter where it intersects the hip rafter.

Here's a 3D drawing of the two crossing rafters as they intersect at the hip rafter.

Checking the miter angle of the crossing jack rafter at the intersection of the hip rafter.

Drawing of the king common rafter at the intersection of the hip rafters.

3D drawing showing the crossing rafters that are rotated into the roof surface.

These next three drawings are priceless. Over the last 5 months, that I've been studying the Traditional layout techniques, the French & German Traditional Layout Books do not show this technique of placing the lumber over the roof surface drawing and drawing perpendicular lines at the edge of the hip rafter and perpendicular lines at the internal edge of the hip rafter on the roof surface. These perpendicular lines automatically develop the correct miter and bevel angles for the rotated rafters. No need to draw perpendicular lines off to the side of the roof surface to develop the true shape of the crossing rafter.