Jack Rafter Layout Board

The jack rafter layout board allows you to draw out the real roof surface of the roof. On this house we had to align our rafters with the open web floor joist and it resulted in 4 different lengths for the first jack rafter length at each of the 3 hip rafters. Once you draw the jack rafter layout board you use the run of the jack rafter in plan view to draw out the jack rafter in the roof surface view to find the dimension of the jack rafter.

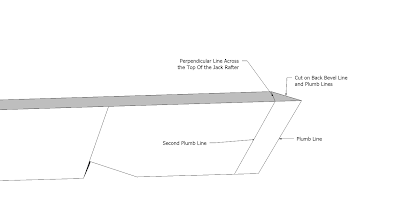

Drawings of jack rafter back bevel layout.

Here's Brian and Erik cutting the jack back bevels with a handsaw. It's important to know how to layout a jack rafter head cut. Once you layout and cut a jack rafter back bevel angle you'll have a better understanding of how the compound angles are developed using a skill saw.

The Seven simple steps to layout the hip rafter correctly.

- Hip Rafter Plumb Line

- Hip Rafter Level Line

- Hip Rafter Shifted Plumb Line

- Hip Rafter Backing Depth Line

- Roof Plane Alignment Point

- Hip Rafter Seat Cut Line

- One Length Method for Hip Rafter Head Cut Line.

One Length Method for Hip Rafter Head Cut Line.

Mark off the hip rafter head cut plumb line from the Roof Plane Alignment Line.

The hip rafter run to the ridge was 71 1/2". With a 5 1/2" - 12 pitch the hip rafter length was 106 5/16" . Mark off the 106 5/16" from the Roof Plane Alignment Line to mark the hip rafter head cut line.

Example of the One Length Method with only the necessary lines to cut the hip rafter. The skill saw cuts at the seat of the hip rafter develop the correct angles to locate the theoretical hip rafter plumb line at the corner of the plate line.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.