I call it the Uhler-Birch Cripple Hip Rafter Method, because in the Hip Roof Framing article in the JLC magazine by Tim Uhler, he said he likes to mark both hip rafter plumb lines on the same side of the hip rafter material so he doesn't have to flip the hip rafter material over to make the second plumb line cut at the hip rafter head cut. Richard Birch's One Length could have been used with all three different layout techniques, but it seemed to be the easiest method to apply to this layout.

I wish I had taken more pictures of the process, but the drawings should show how simple the process is.

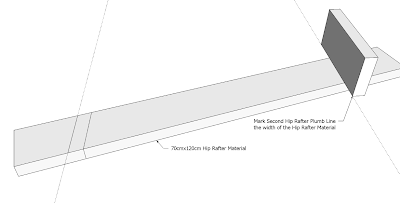

- Mark 2 Hip Rafter Plumb Lines the length of the Cripple Hip Rafter.

2: Use a scrap block the width of the hip rafter material and mark the second Hip Rafter Plumb Line

the width of the Hip Rafter Material.

3: Cut the OutSide Hip Rafter Plumb Line Bevels @ 45°

4: Cut the InSide Hip Rafter Plumb Line Bevels @ 45°

The main concept of the Uhler-Birch Cripple Hip Rafter Method is to use one length-dimension to mark off the length of the cripple hip rafter and use the width of the hip rafter material to layout the bevel lines of the cripple hip rafter.

Here's an example using 70 x 120 cm for the cripple hip rafter material.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.